Here is one of the mine planning applications that I have done. This planning uses optimization in both the Life of Mine design and the annual design. In this project I'm using the optimization features in the Micromine program by simulate the Net Present Value (NPV), Ore Grade, and Ore Tonnage of the design.

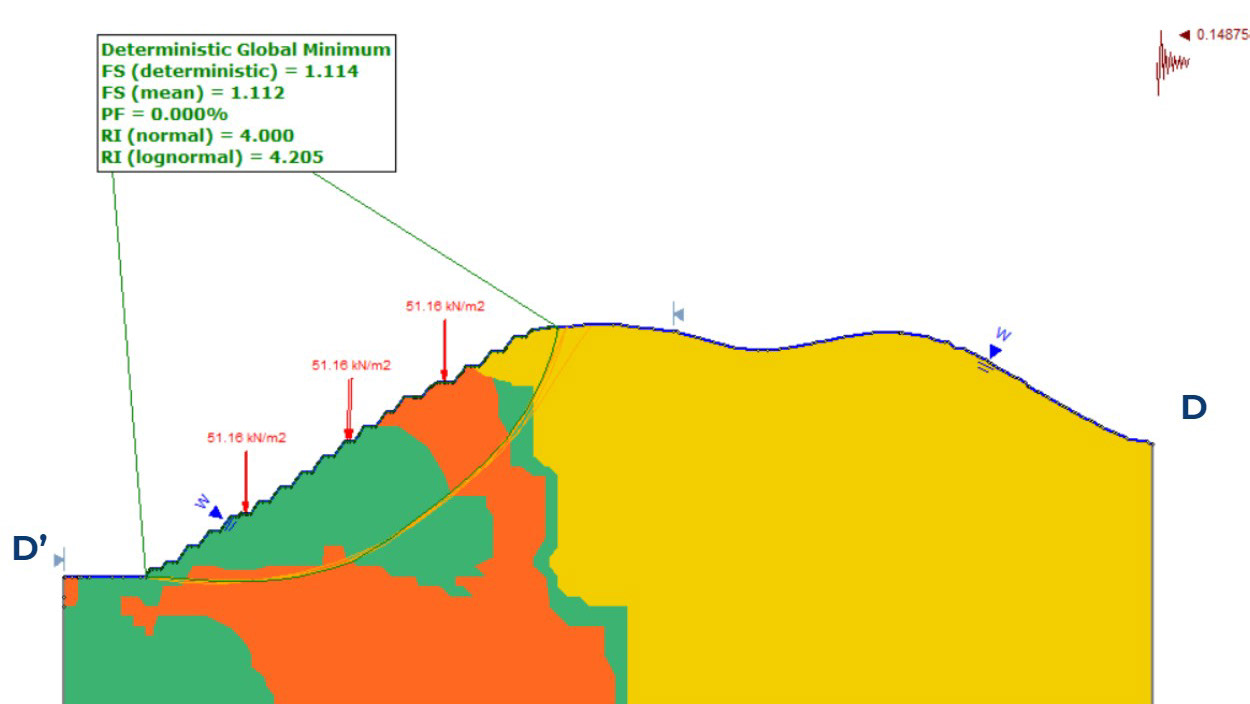

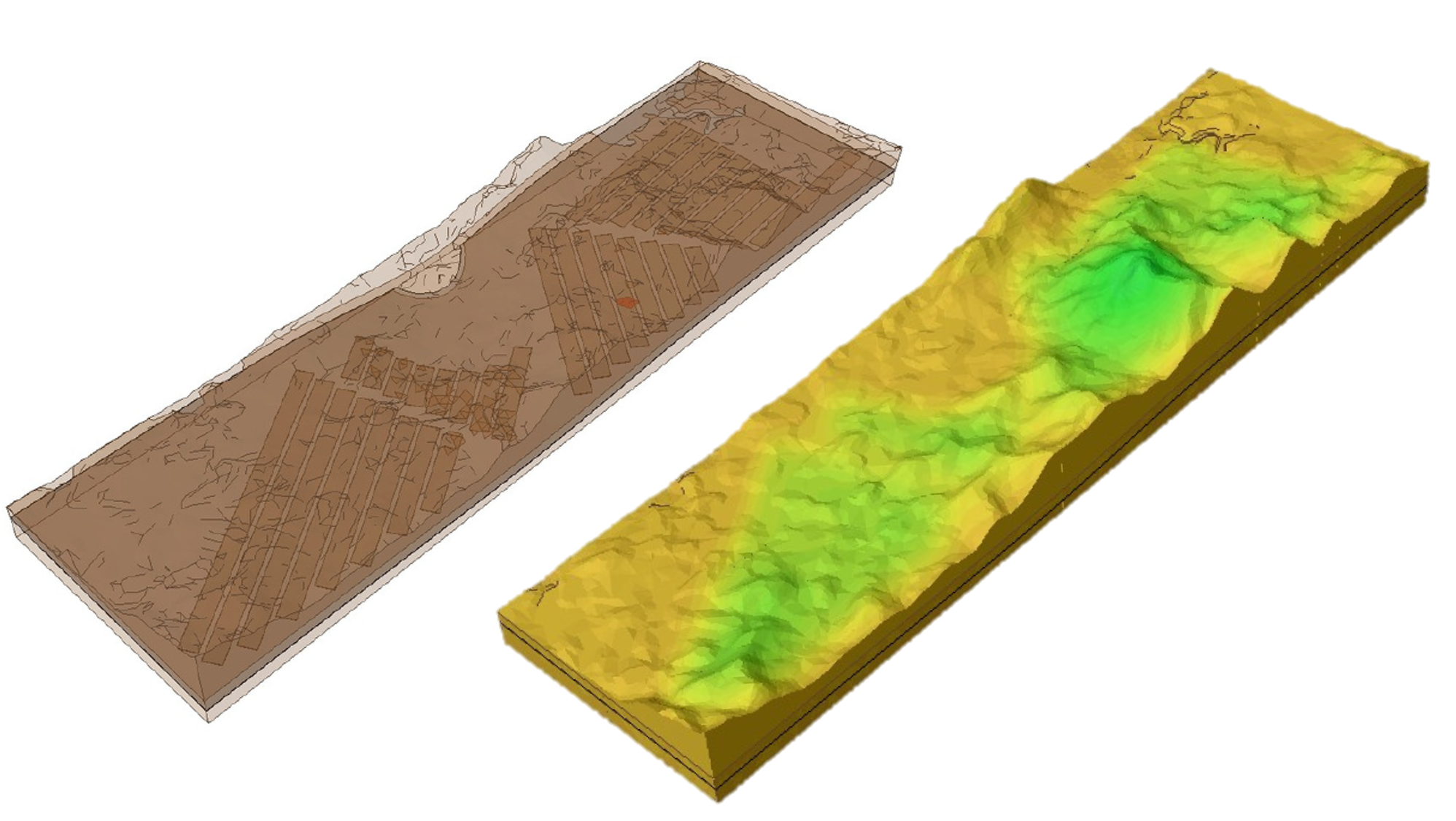

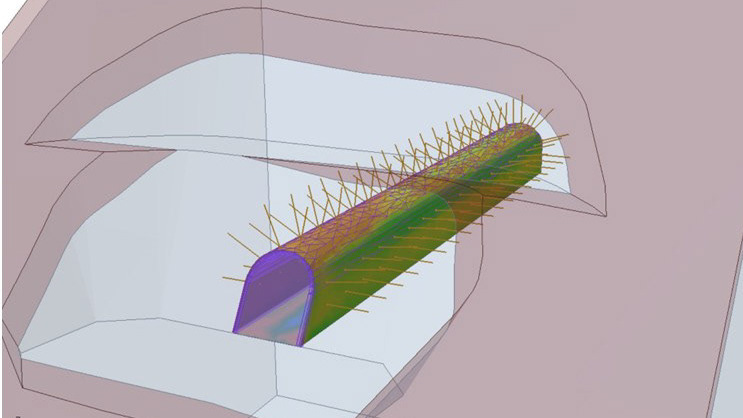

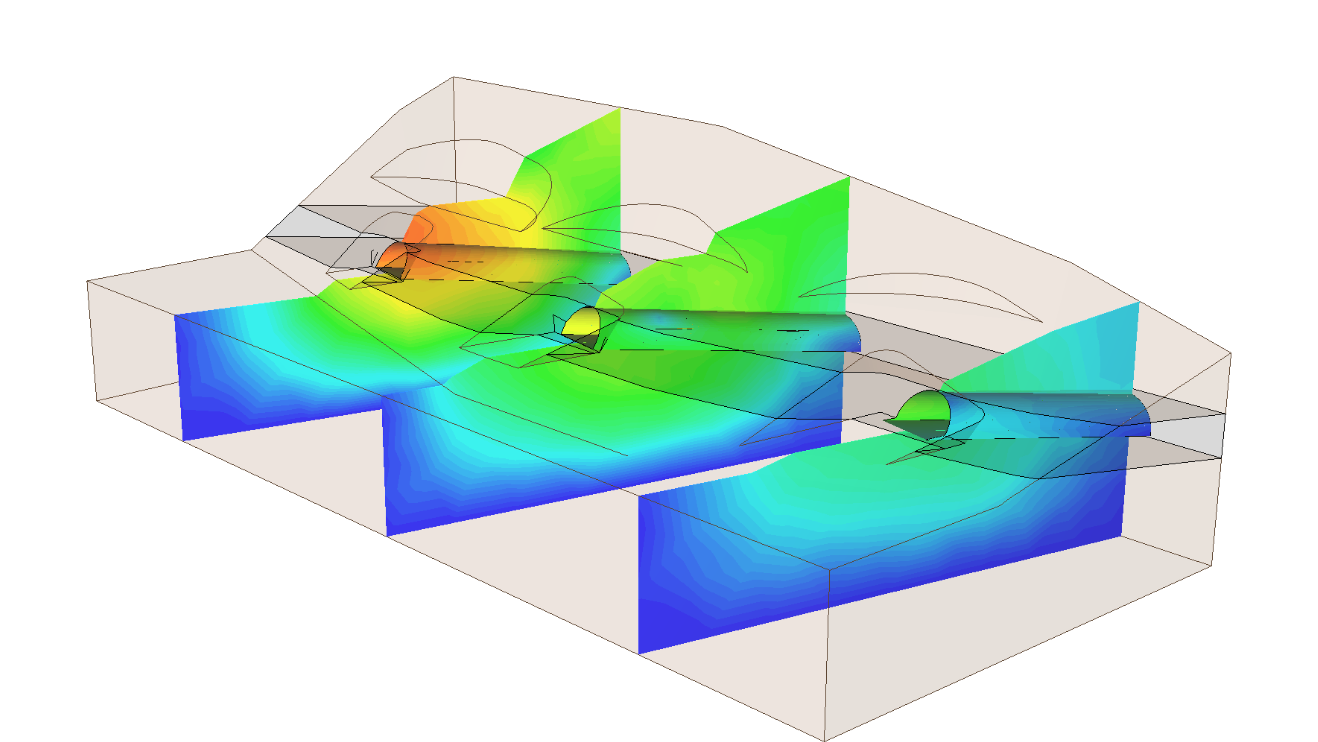

First of all, I performed an initial optimization to generate the pit shells. The parameters used were mining cost, processing cost, selling cost, and revenue. By applying a Revenue Adjustment Factor (RAF), I obtained several pit shells for different RAF values.

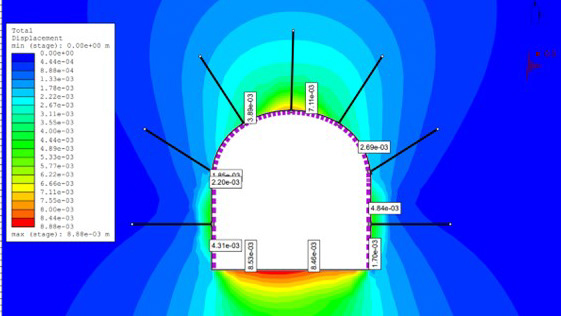

From the generated pit shells, mining simulations were then carried out under several scenarios. The best-case scenario assumes that mining is conducted optimally, always advancing inward with a pattern of moving down one bench and shifting sideways by one block. The worst-case scenario assumes that mining is carried out by completely depleting each bench first (bench depletion). In addition, a separate bench lag scenario was also simulated. Based on the results of these simulations, by integrating the CAPEX and OPEX values, the NPV can be calculated for each pit shell at each Revenue Adjustment Factor (RAF).

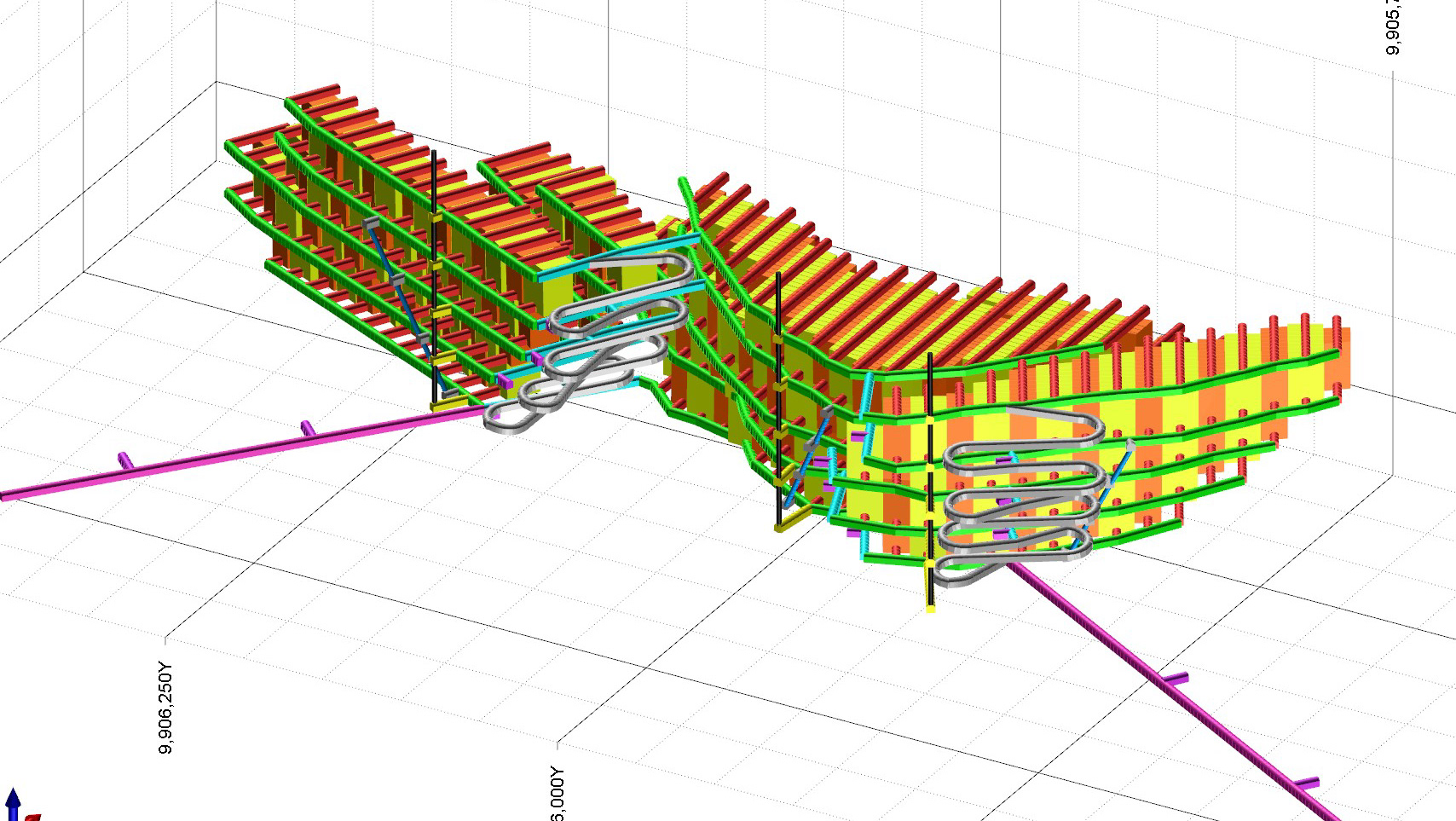

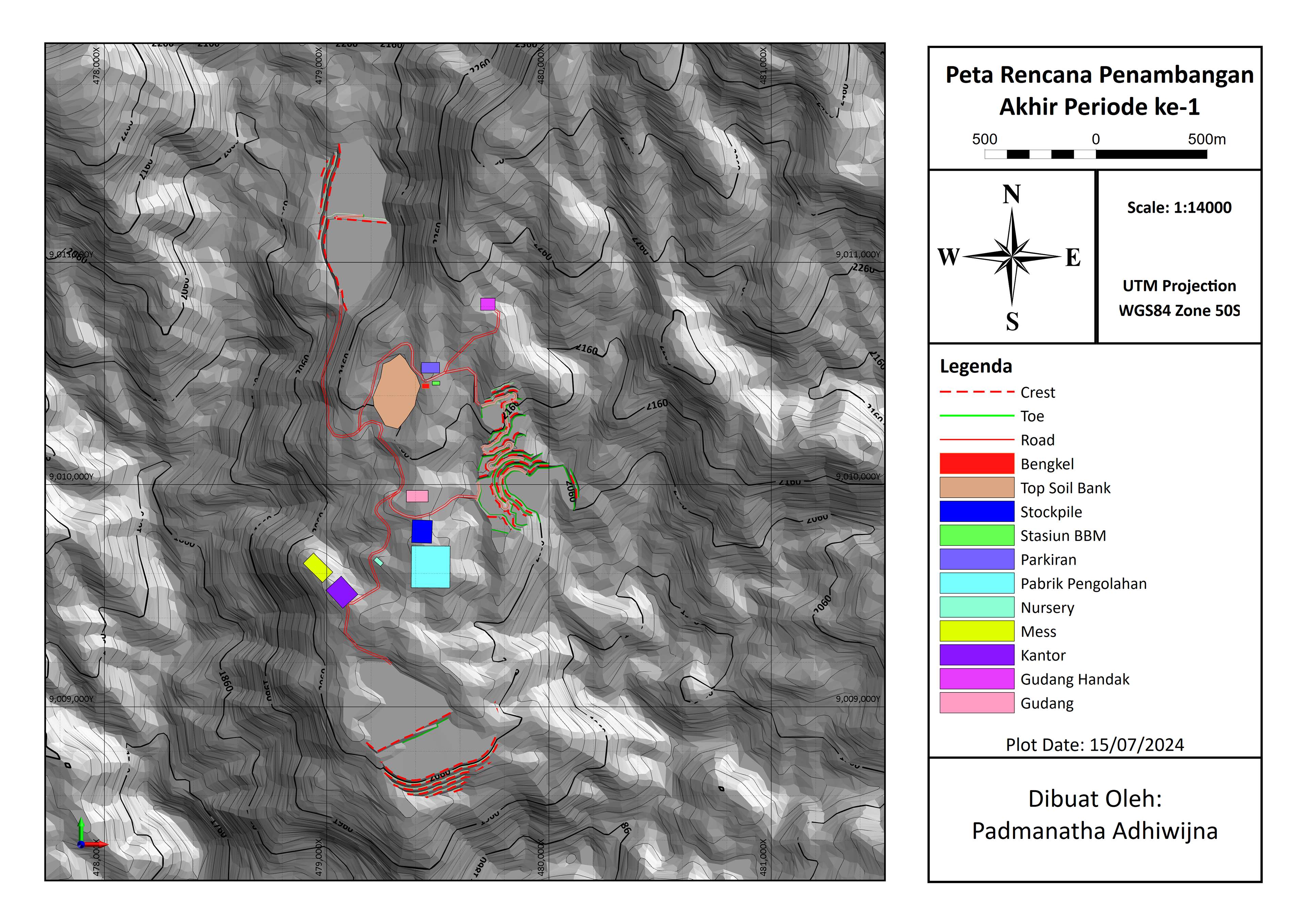

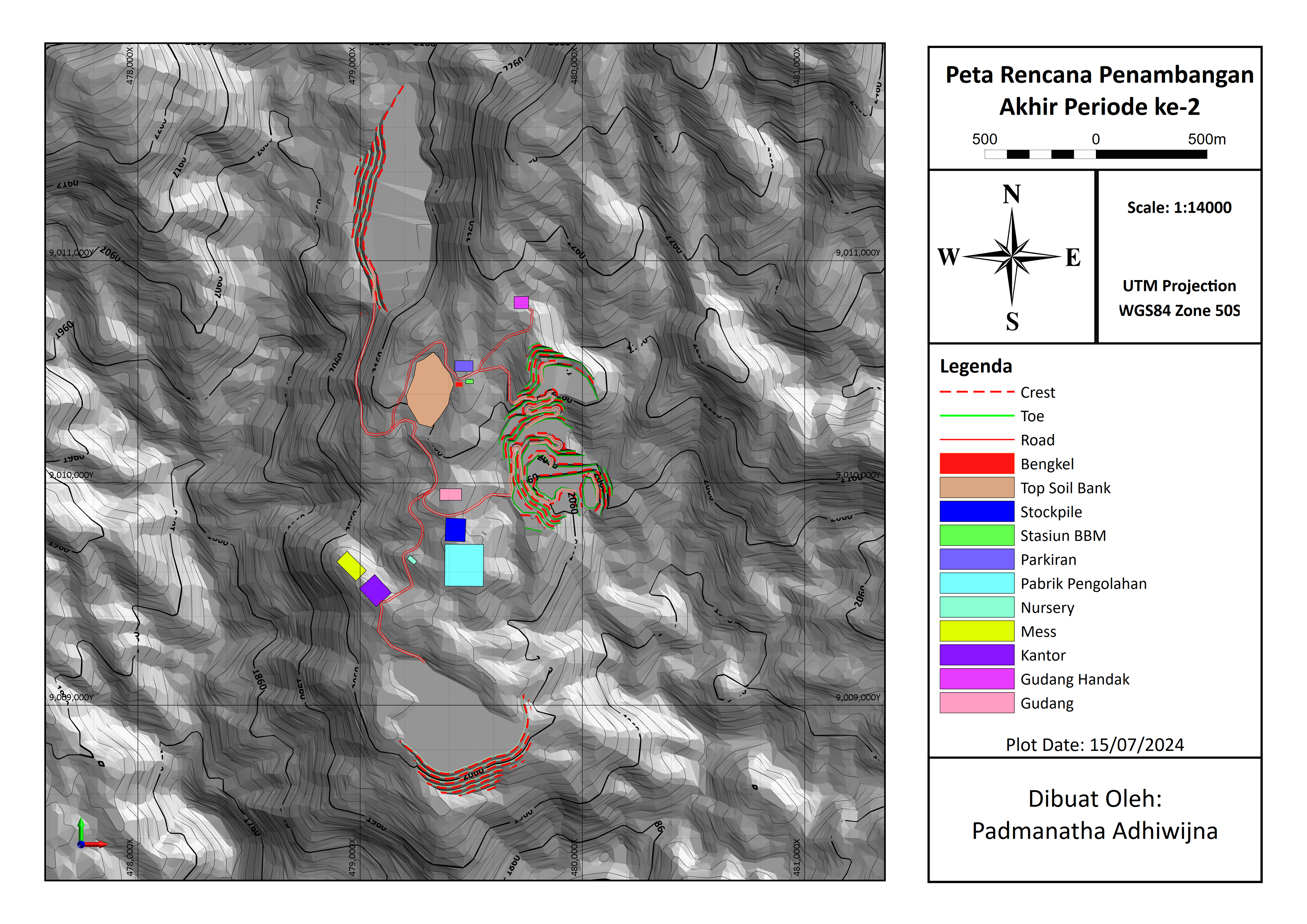

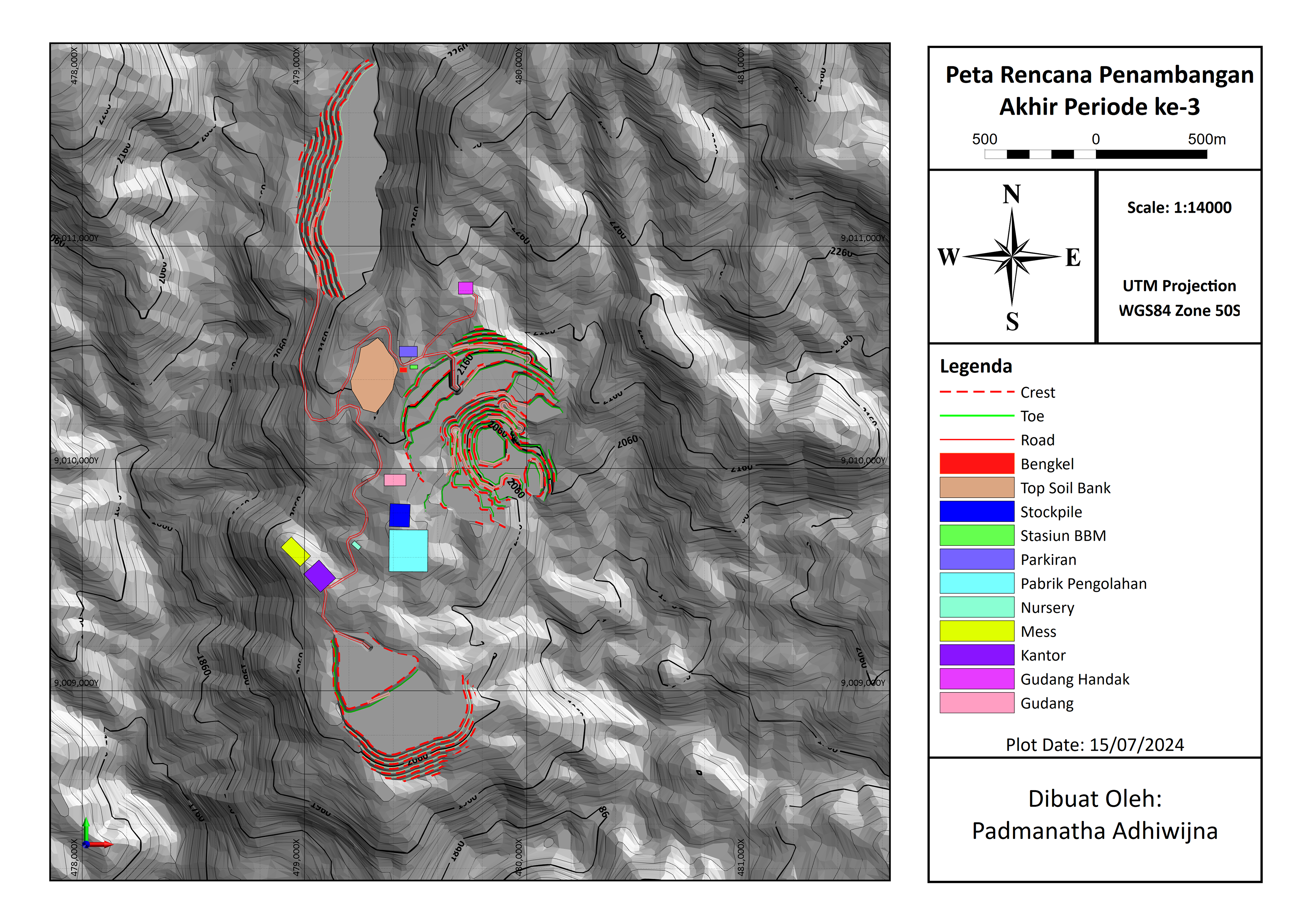

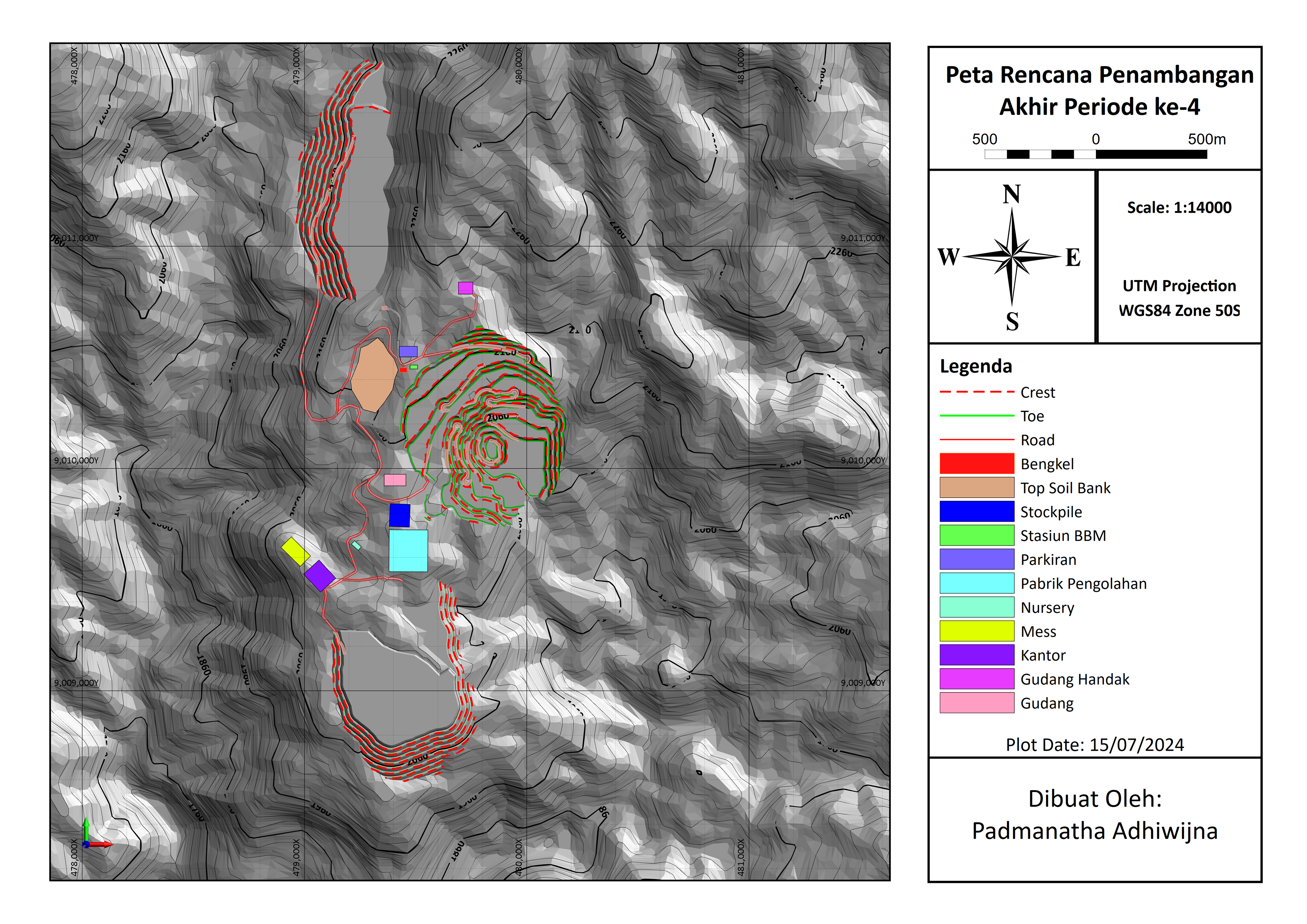

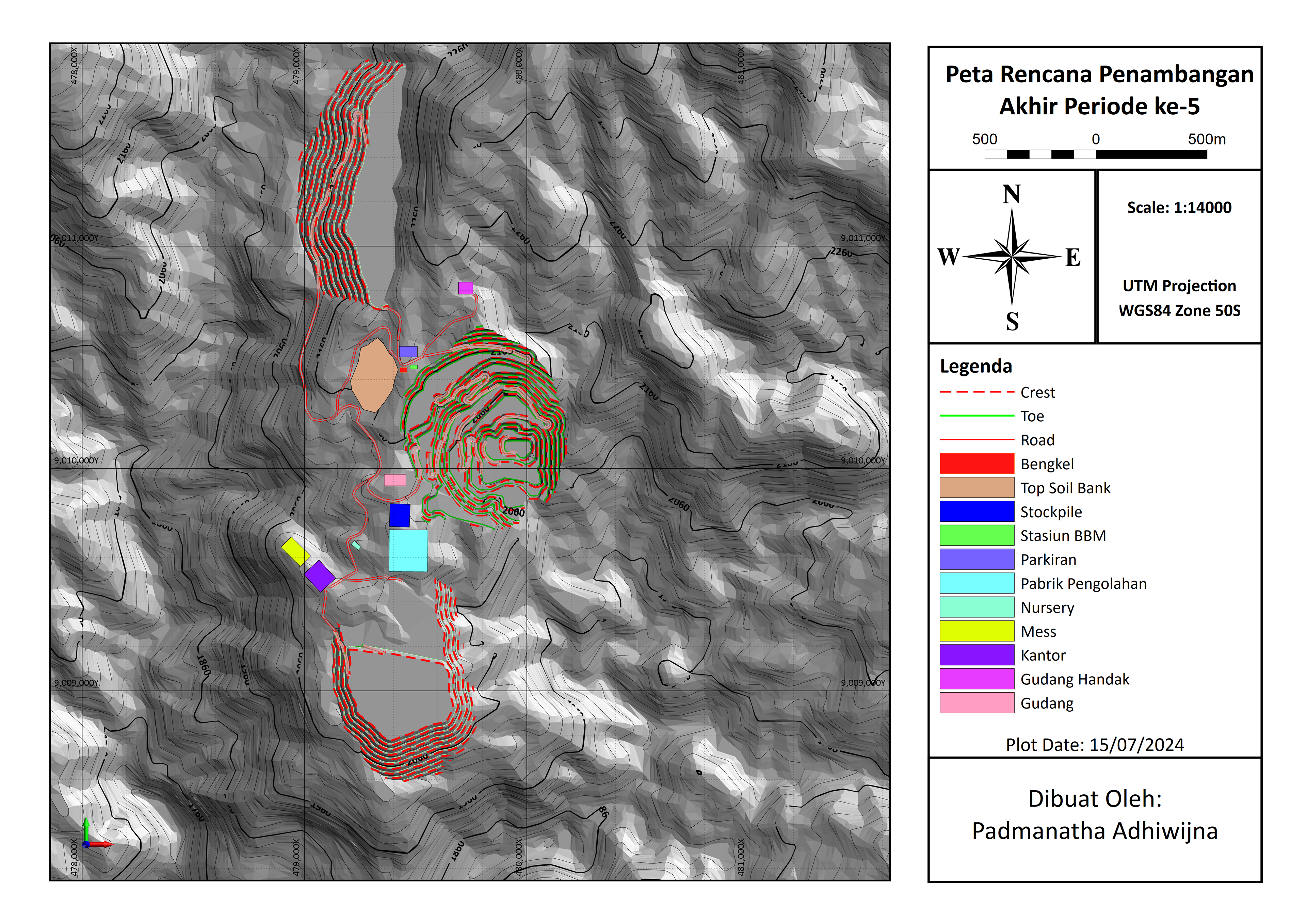

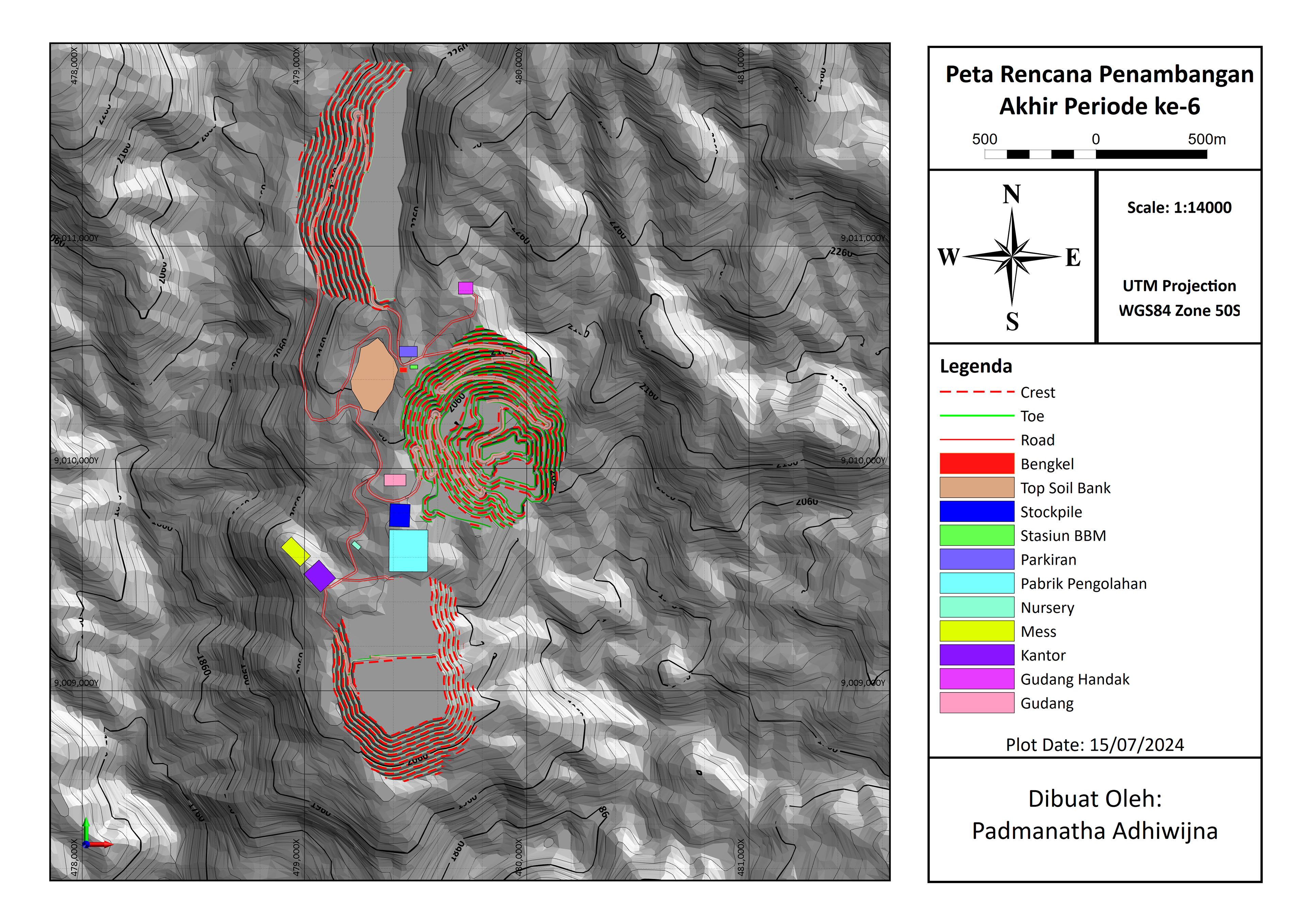

Once the most optimal mining scenario has been selected, I begin designing the pit for the life of mine. After that, I perform scheduling optimization using Micromine to obtain optimal tonnage and grade for each mining period.

Social Media